1. Introduction

Fig. 1: Bearing with embedded solid lubricant

Oilless bearings with embedded solid lubricants (Fig. 1) are maintenance-free and used in conditions where ball bearings cannot be used due to high loads (static pressure, fluctuating pressure) or impact loads. They are also often used in harsh conditions that shorten bearing life, such as at:

-

high temperatures

-

dusty areas

-

under sea water

-

under chemical solutions

-

low sliding speed

-

in locations where space saving is required

In recent years, the demand for robust bearings that can be used at higher speeds or in harsh conditions (dirt, high temperatures, ...) has increased.

2. Solid lubrication system

Fig. 2: Graphite crystal structure

The solid lubricant embedded in bearings is graphite, which has a crystalline structure (hcp) with low shear strength (Fig. 2).

Graphite is chemically stable and has excellent thermal stability. It can be used in the temperature range between 200° to 400° (without additional cooling).

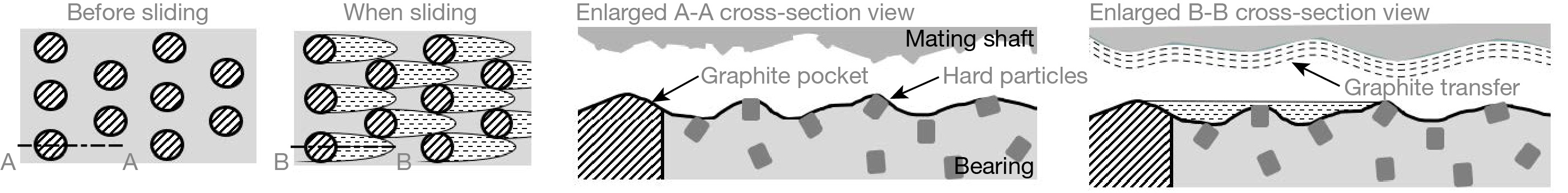

When sliding, graphite is discharged from graphite pockets and transfered to the counterpart material, creating a lubricated surface with low shear strength (Fig. 3).

In some cases, oilless bearings are also used with oil-soaked graphite (only on request) for further improved sliding properties (friction, wear, anti-seizure property).

Fig. 3: Discharge and transfer of graphite

3. Approach to high-performance bearings

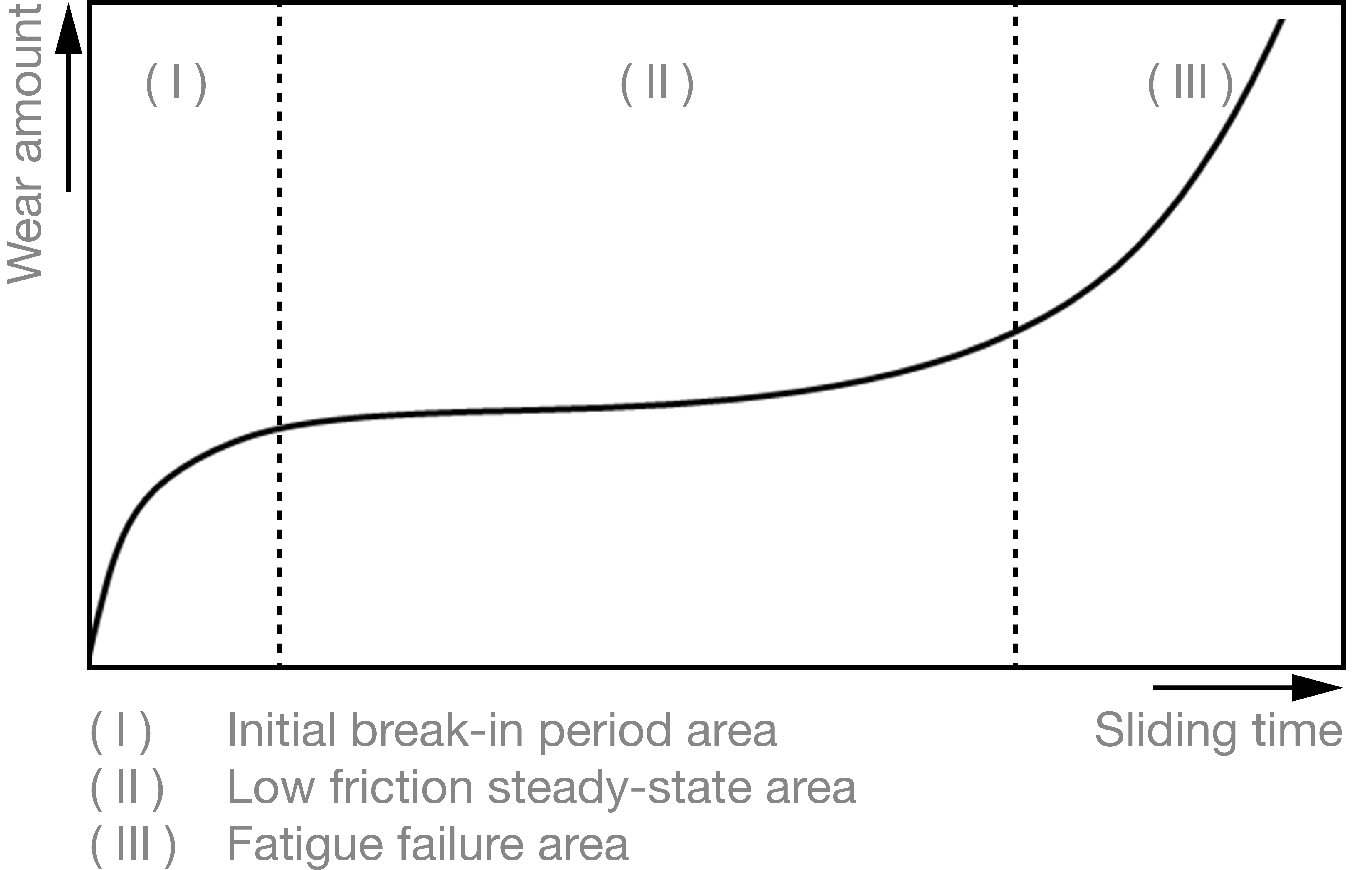

Fig. 4: Bearing wear process

In general, sliding materials transfer from the initial running-in period (I) to the low-friction steady state (II) (Fig. 4).

This means that the ability to promptly achieve a steady state and lower friction is crucial for high-performance bearings.

The friction coefficient of the friction surface with solid lubricants is calculated with the following formula:

μ = τ0 / PH ①

Note that τ0 indicates the shear strength of lubrication films and PH indicates the base surface hardness.

Based on formula ①, we aimed to create high-performance bearings with wear resistance and low friction properties by dispersing hard particles into the base metal alloy. Hard particles dispersed into the copper alloy polish off adhering metals and projections on the counterpart material in the initial running-in period area (I) to ensure smooth surfaces.

In the low friction steady state area (II), the embedded graphite is discharged to create a steady and low friction lubrication state. At this time, the friction coefficient also decreases because the PH in formula ① is higher than that of normal alloy hardness, which prevents the material from moving to the fatigue failure area (III).

As just described, excellent wear resistance and low friction properties are ensured by dispersing hard particles into the copper alloy base metal.

4. High-performance bearings

To respond to a customer request, we developed high-performance bearings (SO#50SP8 and SO#50SP13) by increasing the degree of hardness of copper alloys, which have been used as bearing materials, and dispersing hard particles into them (Table 1).

| Classification name | Material No. | Application |

|---|---|---|

| High-strength brass | SO#50SP2 (CuZn25Al or eq) | Automobile production facilities (used for multiple purposes) |

| SO#50 SP3 | Construction machines (high durability) | |

| SO#50SP8 | Toggle type injection molding machine (excellent running in property and wear resistance) | |

| Aluminum bronze | SO#50SP5 | Outdoor crane, water turbine, water gate (high loads) |

| SO#50SP7 | Mill roller (very high compressive strengths) | |

| SO#50SP13 | Steel mill roller, Grate roller (excellent heat resistance and wear resistance) |

5. Capability of high-performance bearings

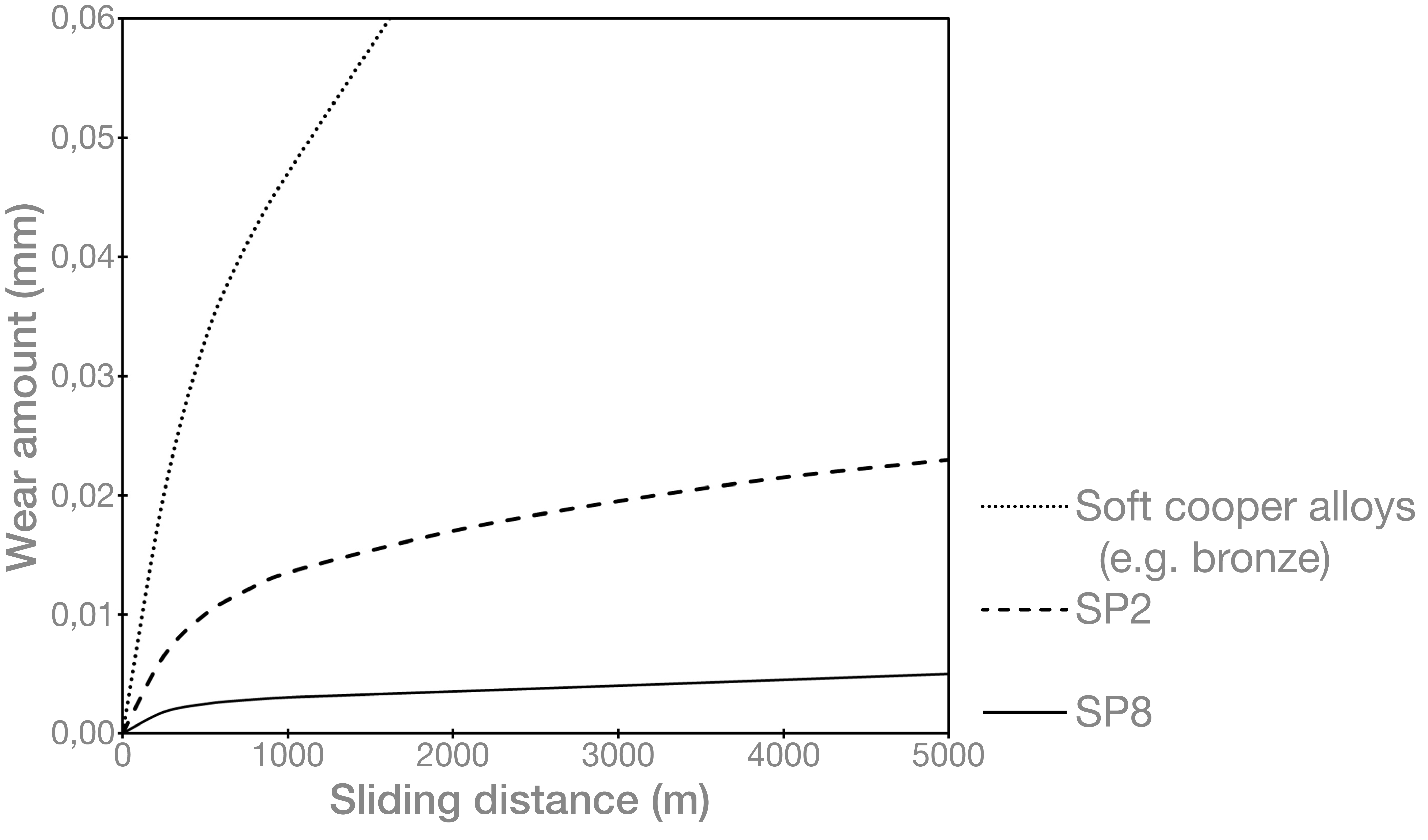

Fig. 5: Wear resistance of SO#50SP8

(1) Oilless bearings with excellent wear resistance for high-load applications

Fig. 5 shows the wear resistance of a bearing (SO#50SP8) made of a high-strength brass copper alloy dispersed with hard particles (the results obtained from a sliding test).

When compared to SO#50SP2 (equivalent to CAC304), which is a high-strength brass copper alloy that has higher wear resistance than other bearing materials, the wear amount of SO#50SP8, which is dispersed with hard particles, is just 25% of it.

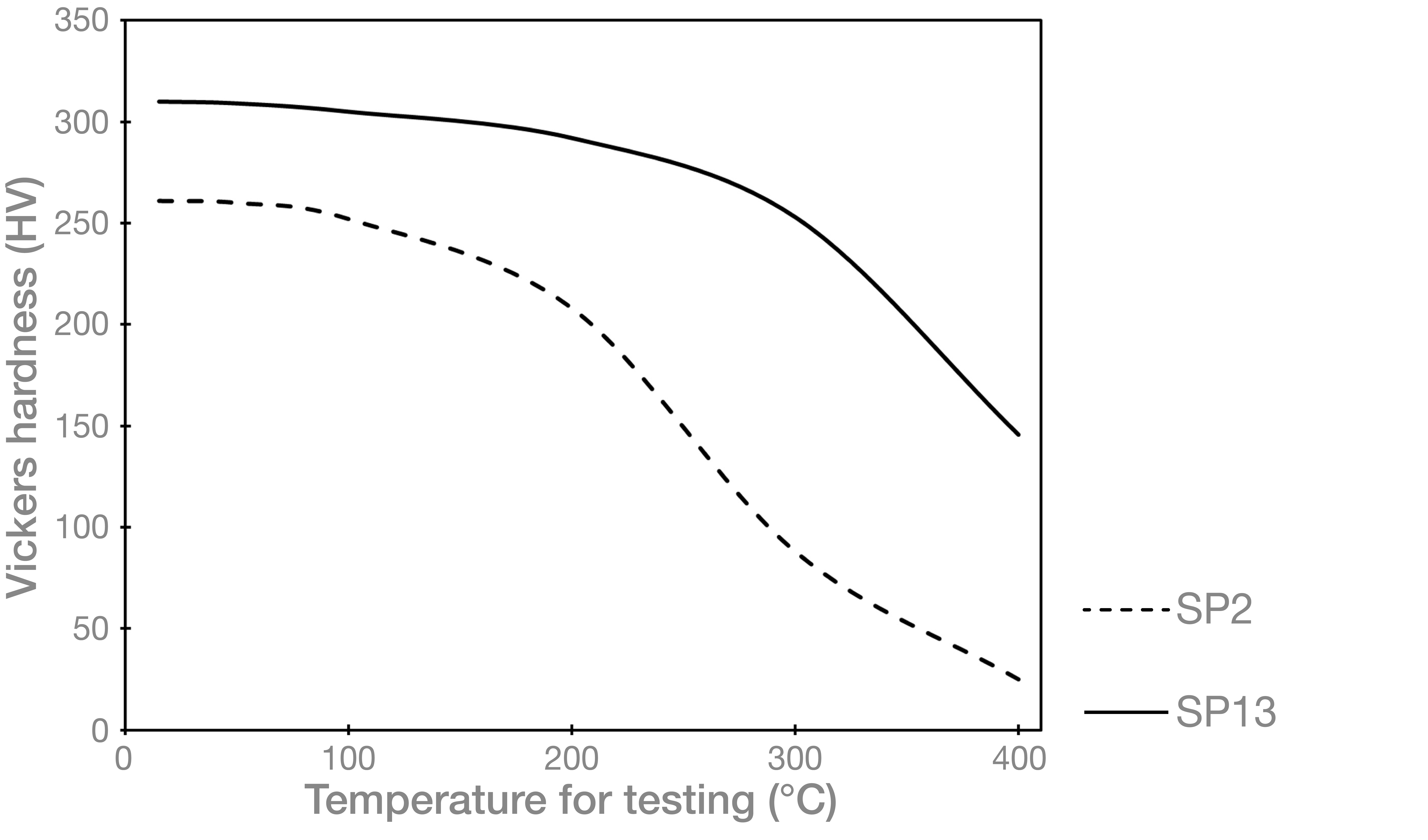

Fig. 6: High-temperature characteristics of SO#50SP13

Test conditions:

|

|

(2) Oilless bearings for high-temperature environments

Oil and grease cannot be used for lubrication, because they deteriorate at high temperature.

Even the degree of hardness of high-strength brass (SO#50SP2) materials significantly decreases when the temperature is higher than 200°C.

The amount of decrease in hardness for SO#50SP13, which is an oilless bearing made of aluminum bronze dispersed with hard particles, is in the range from 200° to 300°C small. Therefore it can be used in high-temperature environments (Fig. 6).

SO#50SP2 (eq. to CAC304)

Hardness: ≥ HB 210

SO#50SP13

Hardness: ≥ HB 280

Fig. 7: Conditions of bushings covered with burned ashes

(3) Oilless bearings with excellent robustness

Aluminum bronze has excellent corrosion resistance at high temperatures.

It is used in drying, combustion, and post-combustion processes as a sliding material for grates in incinerators.

It is also used for bushings for a pusher lever on the device that pushes out burned ashes from under water (environment where wet burned ashes get on the bushing).

Fig. 7 shows the comparison between SO#50SP2 (equivalent to CAC304) and SO#50SP13.

Both were used as bushings for a pusher lever for one year. The hardness of the SO#50SP2 bushing has significantly decreased compared to its hardness when manufactured (HB 210 and above) and there is corrosion damage to the edge.

On the other hand, SO#50SP13 does not have any corrosion or decrease in hardness and the surface under the adhering substance is in good condition with a small amount of wear. The hard particles with adequate hardness keep the amount of wear on the counterpart material small, exhibiting excellent robustness.

6. Conclusion

There are two types of oilless bearings with embedded solid lubricants (graphite).

One is high-strength brass bearings with excellent running in property and the other is aluminum bronze bearings with excellent robustness.

SO#50SP8 and SO#50SP13 bearings, which are made of base metals dispersed with hard particles, exhibit excellent wear resistance and robustness at high temperatures.

They can also be used in special environments where normal bearings cannot be used.

These are created by the synergistic effect of graphite (solid lubricant) and high-performance base materials and exhibit high adaptability.