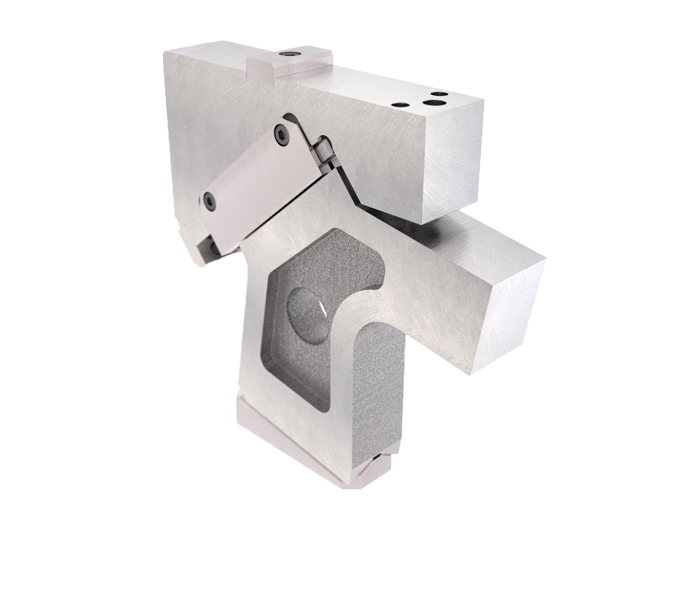

SANKYO-cam units are designed to fit every situation on customers side. During the years there is a continuous development on our products to meet with your requirements. This process ends up in different cam units for each circumstances.

| Name | Mount width | Angle | Details | PDF Download |

| VALCAM™ | 46, 58, 72, 100, 140, 200 – 400mm | 0° - 80° | Aerial CAM-Unit "ALL IN ONE", available in 4 working forces with | |

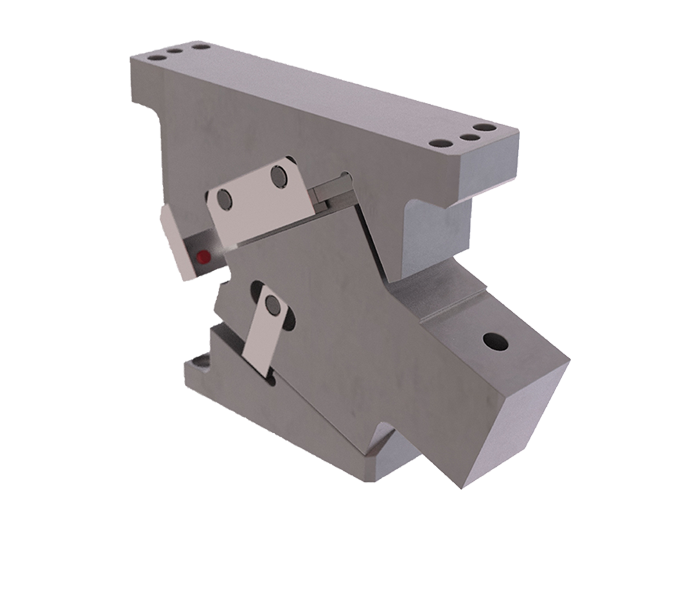

| VALCAM VA™ | 65, 85mm | 0° - 75° | Aerial CAM-Unit, according to VDI regulations | |

| VALCAM-HT™ | 100, 140mm | 0° - 70° | Aerial cam unit capable to withstand thrust load from all directions | |

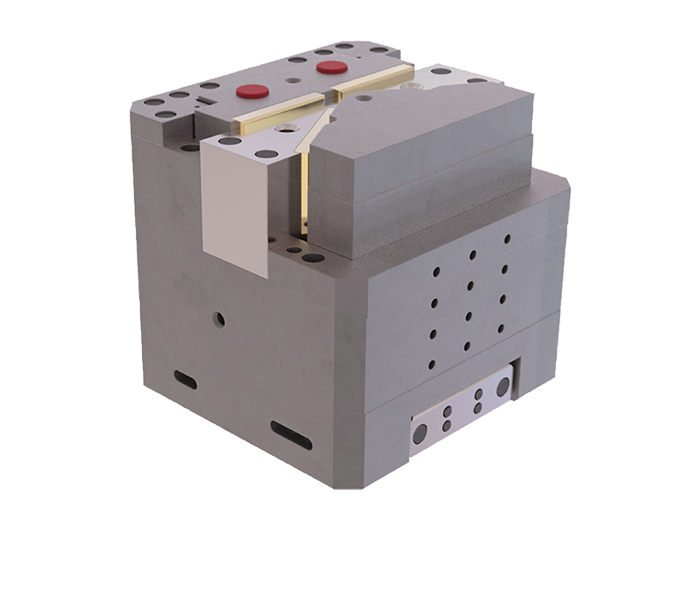

| SUWB | 200 – 600mm | 0° - 60° | Cam slider is removable from the backside. | |

| UCMSV | 60, 85, 110, 165, 200, 250, 300, 400mm | 0° - 75° | Cam slider (spring) is removable from rear of cam. | |

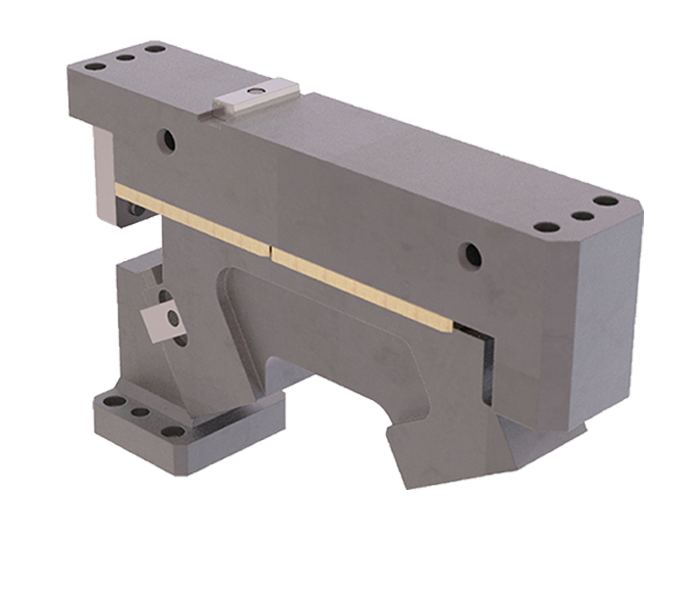

| UCMSL | 500 – 1000mm | 0° - 60° | - | |

| UCMSNR | 46, 58, 72, 100, 140, 200 – 400mm | 0° - 80° | Highly rigid structure with double wear plates and S45C material. | |

| SULNC | 65mm | 0° - 25° | In addition to a long nose (extension by 70mm longer for the standard type than normal product), further protrusion of 150mm (SC option) is available. | |

| SACE | 52mm | 0° - 60° | The spring force is 3 times as long as the same model´s travel. A little less than 10% of the piercing force is achieved. It is most suitable for piercing of high strength steel and thick steel. | |

| SKCA | 52, 65, 100, 150, 250, 300 – 600mm | 0° - 20° | Sliding type with rigid box guide. | |

| CMSD | 52mm, 90mm | 0° - 20° | Easy to remove the cam slider | |

| KCMSL | 500 – 1000m | 0° - 20° | Highly rigid structure with the overseas automotive approved. | |

| SVSC | 50, 85, 110, 150, 220, 330, 400mm | 0° - 20° | Product conforms to VDI/BAK standard. | |

| CT | 120, 145, 245, 320mm | - | Counter cam to bend sheets against the pressing direction | |

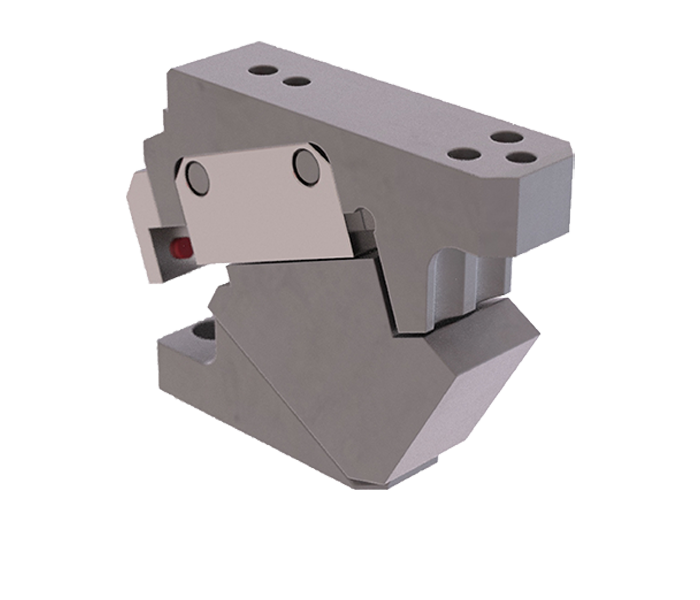

| SACLB | 80mm | 50° - 80° | Long shape of cam slider avoids interference with panel | |

| PSCXG | 80mm | - | Roller cam |

*please note that all PDFs are only available in English

Locating and installation procedure of pierce punch (retainer) in aerial cam units

Locating and installation are now completed Automatic alignment reproducibility of V guide (bottom guide) typeAutomatic alignment means that clearance between the cam holder and the cam slider absorbs machining error for installation of the cam holder and the cam driver. The cam slider body is correctly located with the V guide structure of the driver and the cam slider. Therefore, the position of the pierce punch (retainer) is always reproduced. | Tapped hole and dowel pin (prepared hole, finish) machining for retainer mountingInstruction method for machining

|

SANKYO-cam units are designed to fit every situation on customers side. During the years there is a continuous development on our products to meet with your requirements. This process ends up in different cam units for each circumstances.

*please note that all PDFs are only available in English

Name | Mount width | Angle | Details |

|---|---|---|---|

VALCAM™ | 46, 58, 72, | 0° - 80° | Aerial CAM-Unit "ALL IN ONE", available in 4 working forces with |

VALCAM VA™ | 65, 85, 110, 165mm | 0° - 75° | Aerial CAM-Unit, according to VDI regulations |

VALCAM-HT™ | 100, 140mm | 0° - 70° | Aerial cam unit capable to withstand thrust load from all directions |

SUWB | 200 – 600mm | 0° - 60° | Cam slider is removable from the backside. |

UCMSV | 60, 85, 110, | 0° - 75° | Cam slider (spring) is removable from rear of cam |

UCMSL | 500 – 1000mm | 0° - 60° | - |

UCMSNR | 46, 58, 72, | 0° - 80° | Highly rigid structure with double wear plates and S45C material. |

SULNC | 65mm | 0° - 25° | In addition to a long nose (extension by 70mm longer for the standard type than normal product), further protrusion of 150mm (SC option) is available. |

SACE | 52mm | 0° - 20° | The spring force is 3 times as long as the same model´s travel. A little less than 10% of the piercing force is achieved. It is most suitable for piercing of high strength steel and thick steel. |

CT | 120, 145, 245, | - | Counter cam to bend sheets against the pressing direction |

SACLB | 80mm | 50° - 80° | Long shape of cam slider avoids interference with panel |

SACTFR | 64mm | 50° - 80° | Long shape of cam slider avoids interference with panel |

TSHC | 50mm | 10° - 30° | Long shape of cam slider avoids interference with panel |